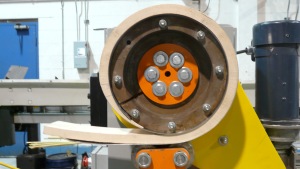

Single Ply Rim Rolling

I’ve been working on a new concept for building banjo rims with only one ply. Shown is a piece of 3″ wide x 7/8″ thick hard maple being rooled into a single ply rim with a 10″ inside diameter. This was done without any pre-steaming of the stock. It was rolled cold with no fracturing of the rim an the outside edge. Up until now this would be considered as impossible to do!

I’ve been working on a new concept for building banjo rims with only one ply. Shown is a piece of 3″ wide x 7/8″ thick hard maple being rooled into a single ply rim with a 10″ inside diameter. This was done without any pre-steaming of the stock. It was rolled cold with no fracturing of the rim an the outside edge. Up until now this would be considered as impossible to do!

Bill, Fantastic but still seems impossible. I want to hear more

Yes, tell us how you did this! Would love to hear how it sounds too.

Looks great Bill!

have u made rims from a thinner continuous stock, rolled 2x/3x instead of one? i was considering trying this myself, but u may have already tried.

Craig:

I’ve tried this proceedure several times and had limited success as it’s very difficult to keep each wrap linned up perfectly. Each wrap wanted to spiral either way and forcing the ply where it didn’t want to go resulted in a delamination after the glue set.

bill will the single ply rim require a special glue? be great if the glue would let the ends touch. i was told by a fiddle maker that it is important for the glue to let the wood touch for vibration.

Bob:

I using standard Original Titebond glue to glue the scarf joints together. The joint is also very closely matched and after gluing it’s quite difficult to find the glue joint. There is virtually no spring back in the rim after rolling.

Bill Rickard

Hi Bill,

You are an engineer’s engineer! Now,please excuse my ignorance (but I am trying to learn). What is the benefit of a cold roll versus the usual steaming?

Tom:

To be 100% honest anything that is slowewr than steaming works im my favour as I’m woring one armed pus from a wheelchair. In my books slow is definately an advantage in a big way! This wood is amazing as if you don’t like the results in the first 5 minutes you just unroll it and start again! Regardless of sound this was invented for me and all one armed banjo builders. Which is probably just me.

Bill Rickard

Thanks Bill, So do you find that the maple is under more, or less tension to spring back (return to flat) when compared to the steam process? When you rap your knuckle on the finished rim, does it ring more or less than the steamed wood? Or maybe no difference? It is very interesting that you can cold roll it like a flat sheet of steel! I manage a large machine shop (mostly steel – some bronze and brass), so I am fascinated in all of your processes and fixturing. But mostly I love to play banjos! Someday I’ll get one of yours! At the moment I am waiting on a new one from your pal Dan in Paris TN. It is the 9 string he is working on. I’m sure all the hardware cones from your shop! Thanks Bill, best wishes, Tom

Nice to read, but still don’t know how you do it…